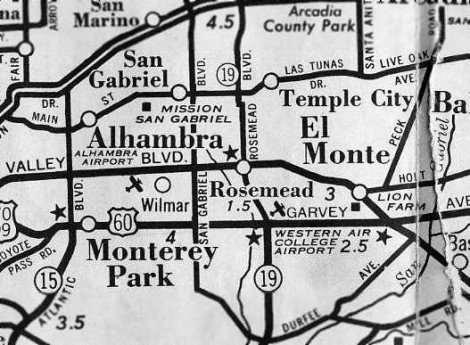

We recently had the opportunity to sit down with industry icon and leader Arthur Kajiwara at his office in South El Monte, California. This site is not just your typical warehouse; it houses all the offices, parts warehouse and design studio with years of past designs stored for quick reference. Kajiwara is the principal designer for all that goes out the door, and he is definitely “old school” when it comes to producing working drawings. He does all drawings by hand on a drafting board using equipment templates he has created and stored over the years. In another large building is a complete operating plant that is a virtual test bed for the many innovations that Kajiwara has brought to the market. This is also the location of the famed Kajiwara Equipment “Open House,” and anyone who has ever attended one of these surely has some pleasant memories of the day.

In looking over many of the installations done over the years, Art had fond memories (once it was completed) of a large laundry and cleaning facility that could certainly be classified as challenging. First off, this job was in Kao-Hsiung Taiwan! This was a 3000 square foot endeavor that began life as a design project – along with supplying the equipment and major components – and shipping it all to Taiwan. This created several challenges in itself. The 25 HP Parker Boiler was set up to burn propane, as there is no piped in natural gas available. All propane is brought in small cylinders via motorcycles and grouped together with one large manifold. Lack of pressure meant Kajiwara had three inch pipe, and then up to six-inch pipe to compensate! Water supply was a similar issue; no pressurized system means all water has to be pumped to tanks on the roof for a gravity fed system.

Once all this was designed and the equipment was shipped, Art Kajiwara and a two man crew headed off to Taiwan where their role was to oversee the installation through start-up. Only upon arrival were they to learn that there was no crew available, they were going to have to complete the installation. Their only consolation was five workers, who did not speak a word of English, and were available to assist the Kajiwara team. Undaunted, they continued through the challenges of completing the project. Any additional materials, valves, gas regulators, etc. needed had to be flown in from Japan at great expense due to the currency exchange rates.

One particular problem was mounting the 45-pound Frigosec Dry Cleaning Machine. What appeared to be finished concrete floors was really just a layer of red bricks with a thin layer of mortar over the bricks. This had to be dug out and a proper concrete floor poured for a proper installation. Another was installation in the lofty ceiling spaces. Some of the ladders available were the locally supplied units…made from bamboo and rope!

The project was successfully completed, and after one month living in a very foreign country and the differences in building methods and culture, Kajiwara and crew packed up and came home. The plant is operating to this day, just as it was designed to do.

Judging by the number of jobs archived at Kajiwara Equipment, this is just one of many stories that could be told. All from the “old school” drafting board that Arthur Kajiwara uses to this day to design award-winning plants like Corona Del Mar Cleaners in Newport Beach, California. (See Cleaner & Launderer November 2013).